Small control system

SAFELINE VARIO

You need a holistic safety solution with a multitude of inputs to monitor safety functions such as emergency stop, light curtains and safety gates? Then we have the perfect solution for you: SAFELINE VARIO is the compact safety control system from DINA that monitors everything with maximum safety up to Performance Level e or SIL 3.

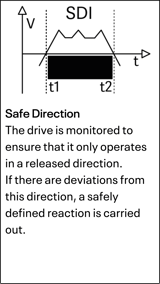

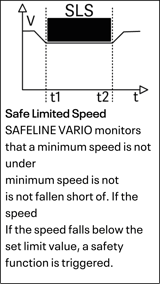

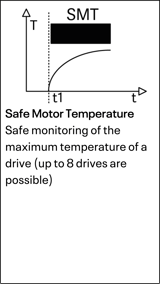

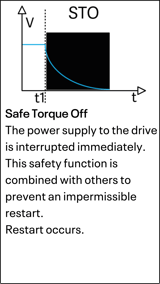

With up to 30 inputs, SAFELINE VARIO is perfect for machines of all kinds. Fully expandable to up to 15 add-on modules for functional safety applications, the compact safety control is the ideal solution for all safety issues. Whether standstill, position, direction, brake or, above all, speed monitoring, SAFELINE VARIO can handle it all.

In addition, a license-free configuration software is included with every purchase, with which you can easily manage your safety applications. SAFELINE VARIO is compatible with the controls and safety systems of the most common manufacturers.

Machine safety. Without compromise.

SAFELINE VARIO is the most versatile and at the same time most compact safety compact control currently available on the market. With a width of only 45/67.5mm (central module), the multitude of applications in such a small space is unique.

The module is available in different versions, among others with integrated speed monitoring and state-of-the-art comparator function.

Another advantage compared to conventional safety solutions is the independence that comes with our products. SAFELINE VARIO can be connected to all common machine controls and safety components, regardless of the supplier. We do not tie you down in any system, but make what you need possible.

General Features

![]()

![]()

Safety Features

Evaluation

Fieldbus Connectivity

Electronic reuqirements

| Module | ZMV | ZMVK |

| Operating voltage at A1, A2 |

24V DC, -15% + 10% |

24V DC, -15% + 10% |

|

Input current via A1 |

≤ 4A / internal fuse: 6A |

≤ 4A / internal fuse: 6A |

|

Power consumption in W |

2,9 |

7,7 |

|

Weight in gram |

350 | 570 |

|

Module |

ZMVA | ZMVD |

| Operating voltage at A1, A2 |

24V DC, -15% + 10% |

24V DC, -15% + 10% |

|

Input current via A1 |

≤ 4A / internal fuse: 6A |

≤ 4A / internal fuse: 6A |

|

Power consumption in W

|

3,0 | 3,0 |

|

Weight in gram |

450 | 450 |

Semiconductor Outputs

| Module | ZMV | ZMVK |

| Outputs PL | IO1-IO4 PLe | O1–O6 PLe |

| Type of Output |  |

|

|

Switching and continuous current Ω/ L |

0,1A | 1A |

|

Summe Schalt-, Dauerstrom Ω/ L |

0,4A | 3A |

| Min. switching current Ω/ L | 1mA | 1mA |

Contact Outputs

| Module | ZMV, ZMVD | ZMVK |

| Outputs | K1, K2 | K3 - K6 |

| Output execution Performance level: e |  |

|

| Minimum switching current | 10mA | 10mA |

| Breaking capacity according to DIN EN 60947-4-1/ EN 60947-5-1 |

DC13: 24 V / 2 A |

DC1: 24 V / 6 A DC13: 24 V / 4 A / 0,1 Hz |

| Sum of switching and continuous currents | K1, K2: ≤ 6A |

K3, K4: ≤ 6A, K5, K6: ≤ 6A |

| Lifetime at DC13: 24V/ 1A | 1,5 x 10^5 | 1 x 10^5 |

| Lifetime at DC13: 24V/ 4A | 10^4 | 4 x 10^4 |

| Lifetime at DC13: 24V/ 1A | 1,5 x 10^5 | 1 x 10^5 |

| Mechanical lifetime | > 50x10^6 | > 10^7 |

| Maximum switching cycles with DC13: 4A | 360 Cycles/h | 360 Cycles/h |

| Maximum switching cycles with AC15: 3A | 360 Cycles/h | - |

| Contact fuse protection | 6A inert | 6A inert |

| Short-circuit resistance: | 200A/BG 800A/6A gG |

1000A SCPD 6A |

|

Rated insulation voltage |

250V AC | - |

|

Surge voltage resistance Pollution degree 2 Environment |

4KV | - |

| Response / release time typical | 15 ms/ 12 ms | 10ms/ 3 ms |

Environmental Data

| Operating temperature | -10°C to +55°C |

| Storage Temperature | -40°C to +85°C |

| Vibration (in 3 levels) | sin 10 to 55 Hz, 0.35 mm (0.014 in), 10 cycles, 1 octave/min. |

| Shock resistance of the output relays (in 3 levels) | ≤ 5g, 11ms |

| Connection cross-section | 0.25 - 2.5mm2 with ferrules |

| Terminals | Spring-loaded terminals, pluggable |

| Connection Fuse | Only 60/75°C Copper |

| Casing material | Polyamid PA non-reinforced |

| Protection Class | Casing and Terminals: IP20, Installation Site: minimal IP 54 |

| Voltage at the inputs for safety mats | Safety mat activated: 24 V Safety mat nominal: 11,5 V Safety mat undamped: 9,5 to 14 V |

| Response time for safety mats | < 25ms |

| Voltage at the inputs | 24V DC -15%, + 10%, ≤10% Ripple |

| Current consumption of the inputs | Max. 4.0mA |

| Input voltage at terminal P at DSV, DRV, SIV, IOV and NIV | 24 V DC (-15/+10%) |

| Input current at terminal P at DSV, DRV, SIV, IOV and NIV | < 4 A |

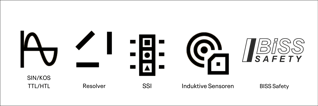

| Input frequency at I9 - I12 on the central module | ≤ 500Hz via 2 sensors e.g. proximity switch |

| Input frequency at I9 - I16 on the central module | ≤ 50KHz for HTL signals via incremental measuring system |

| Input Frequency at DNSL-DSV | ≤ 500KHz sin/cos 1Vpp or TTL signals |

| Input frequency at DNSL-DRV | ≤ 1200Hz sin/cos 1 to 10Vpp |

| Input frequency at DNSL-DRV | ≤ 1200Hz sin/cos 1 to 10Vpp |

| Accuracy of analogue Inputs | ±3% of full scale over the temperature range -10 to +60°C |

| Input impedance of the analogue inputs | At 4-20mA approx. 500Ω, at 0-10V > 5KΩ |

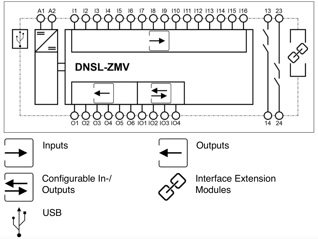

Drawing ZMV

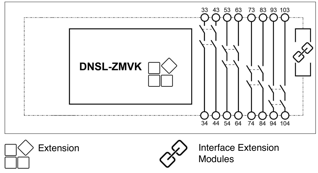

Drawing ZMVK (Extension)

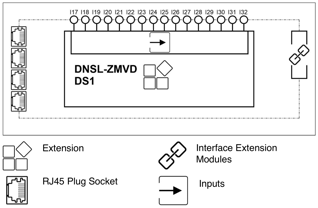

Drawing ZMVD (Extension DS1)

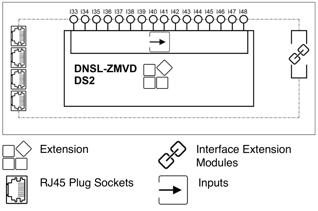

Drawing ZMVD (Extension DS2)

Safety-relevant Parameters according to DIN ISO 13849-1

| Module |

MTTFd [a] |

Kat./PL |

PFHd |

|

DNSL-ZMV |

98 |

4/e |

2,4 x 10-8 |

|

DNSL-ZMVK |

37 |

4/e |

7,7 x 10-8 |

|

DNSL-ZMVD DNSL-ZMVD2 |

92 86 |

4/e 4/e |

2,7 x 10-8 3,0 x 10-8 |

Contact Service Life

Electrical contact service life of the output contacts according to DIN EN 60947-5-1 Appendix C.3.

DNSL-ZMV, -ZMVK, ZMVD K1 and K2

DNSL-ZMVK K3 until K6

-

DNSL-DSV: Drive monitoring for 2 drives with incremental encoders

(8 safe inputs, 5 safe outputs)

-

DNSL-DRV: Drive monitoring for 2 drives with resolvers

(8 safe inputs, 5 safe outputs)

-

DNSL-SIV: Drive monitoring for 2 drives with SSI absolute encoders

(8 safe inputs, 5 safe outputs)

-

DNSL-IOV: In-out module

(8 safe inputs, 7 safe outputs)

-

DNSL-INV: Input module (16 safe inputs)

-

DNSL-RMV: relay module (2 outputs with 2 safe contacts each)

-

DNSL-FBV: various fieldbus connections

-

DNSL-NIV: Network module & DNSL-CMV: Cascade module enable decentralized set-up

Your advantages summarised

Fully customisable

Fully customisable

A wide range of safety functions, up to 30 inputs and 15 optional add-on modules make SAFELINE VARIO the ideal solution for any machine. You can configure the unit to suit your needs and the results of your risk assessment.

Fast configuration & verification

Fast configuration & verification

Take advantage of our licence-free SAFELINE DESIGNER software - pre-programmed function blocks make it easy for you to create applications. We are also happy to create individual modules for your machine.

Independent

Independent

SAFELINE VARIO can work with any common machine control and safety system. You do not have to worry about compatibility and possible dependency on a single manufacturer.

Simple diagnostics & communication

Simple diagnostics & communication

With the right fieldbus module, visualisation becomes a breeze. For this reason, we offer a wide range of protocols.

Test it now in a three month free trial!

Together with you, we configure a sample device tailored to your requirements and send it to you for testing. And that's free of charge for 3 months.